Dwójłomność

Oferujemy gotowe systemy jak i komponenty

Dwójłomność

Technologia pomiaru dwójłomności opracowana przez Hinds Instruments została przyjęta przez liderów branży na całym świecie jako podstawa. Dwójłomność mierzy się jako różnicę współczynników załamania składników w materiale.

Systemy pomiarowe firmy Hinds Instruments dostarczane przez SPECTROPOL pracują w całym spektrum światła DUV, VIS i NIR) i są w stanie mierzyć, z niezrównaną dokładnością, rozdzielczością i powtarzalnością praktycznie wszystkie materiały optyczne, w tym: szkło, elementy ekspozycyjne, formowane wtryskowo tworzywa sztuczne, włókna ciągnione, światłowody, siatki litograficzne, półwyroby soczewkowe, soczewki, warstwy krzemowe, minerały, kryształy laserowe, kryształy ciekłe, kryształy dwójłomne i inne.

- Opóźnienie optyczne w rozdzielczości 0,001 nm

- Szumy na poziomie 0,005 nm

- Systemy wytrzymałe, dynamiczne i skalowalne, aby spełnić wysokie wymagania aplikacji.

Typ | Kształt próbki | Materiał | Wymiary próbek | Retardacja |

|---|---|---|---|---|

Exicor AT | Płaska | Szkło, plastiki, polimery | do 500 x 500 mm | 0.005 do 300nm |

| Exicor HD | .... | ... | ... | ... |

| Exicor DUV | Płaska | Pomiary DUV | próbki litograficzne do 400mm x 400mm | 0.005 do 4000nm |

| Exicor MT | Płaska | OEM | OEM | 0,005 do 4000 nm |

| Exicor PV-Si | Płaska | Krzem, sztabki | do 500 mm x 150 mm dla sztabek prostokątnych | 0.1 to 775nm |

| Exicor OIA | Obła | Elementy optyczne | średnica do 400mm | od 0.005 do 300+nm (VIS) od 0.005 do 90+nm (DUV) |

| Exicor GEN | Płaska | Szkło, powłoki | do 2500mm x 3000mm | od 0.005 do 300 nm |

Masz pytania ?

Exicor® AT

Exicor® birefringence measurement technology, introduced in 1999 with the model 150AT, provides leading edge customers with the world’s most technically advanced, production-worthy capability for measuring birefringence. Unprecedented sensitivity in the Exicor systems is a product of Hinds Instruments’ PEMLabs™ Technology that pioneered the ultra-low birefringence photoelastic modulator (PEM). The award winning sensitivity of Exicor is enhanced by the modulation purity of the PEM, a result of the resonant nature of the modulator. The modulation frequency of the PEM is 50 kHz, providing fast measurement capability. The unique design of the dual detector optical system, in conjunction with PEM science, provides a valued feature: no moving parts in the optical system. The absence of moving components produces high mechanical reliability as well as repeatability of measurements and allows magnitude and angle to be measured simultaneously.

Exicor measures retardation integrated along an optical path through the optical sample under investigation. It is designed to measure and display both the magnitude and orientation of the retardation axis. A unique design (patents pending) eliminates moving parts in the optical train and avoids the necessity to switch between measurement angles. A HeNe laser beam is polarized and then modulated by the PEM. The modulated beam is transmitted through the sample and divided by a beam-splitting mirror. Each beam passes through a combination of an analyzer, optical lter, and photodetector. The electronic signals are processed through a lock-in er that provides very low level signal detection. A software algorithm, developed by Hinds Instruments,converts the signal levels from the electronics module into parameters from which linear birefringence can be determined. The computer selects from two inputs, allowing sequential measurements from the two signal channels. The data is analyzed, and then retardation magnitude and axis angle are displayed and stored in file. When operated in the automated mapping mode, the x-y translation stage will move the sample to the next predetermined measurement location. Results are displayed instantaneously in user-specified formats.

| SPECIFICATIONS | |

Retardation Range: | 0.005 to 300+ nm |

| Retardation Resolution / Repeatability1, 2: | 0.001 nm / ± 0.015 nm |

| Angular Resolution / Repeatability1: | 0.01º / ± 0.07º |

| Measurement Rate / Time3: | up to 100 pps / sample size dependent |

| Light Source Wavelength4: | Various (632.8 nm standard) |

| Measurement Spot Diameter5: | Between 1mm & 3mm native (can be as low as <50 µm) |

| Modulation Technique: | PEMLabsTM Photoelastic Modulator |

| Measurement Units: | nm (retardation),° (angle) |

| Features |

|

Exicor 120AT

The Exicor 120AT is versatile enough to excel in both production floor and R&D lab environments. The bench top design and intuitive automated scanning software make this product ideal for day-in-day-out evaluation of small parts (up to 120 mm x 100 mm). The standard high speed scanning package, Scan in Motion™ or SIM, makes high spatial resolution scans (<1 mm grid spacing) practical.

Applications: Stress Retardation Measurements (Plastic films, Lens blanks, Laser crystals,Cell phone display windows)

Features:

- Bench top design

- System Size WxDxH (mm) 1500x1500x1500

- Max. Sample Size WxDxH (mm): 500x500x500

Exicor 150AT

The Exicor 150AT is the work horse of the Exicor® birefringence measurement system family of products.

This system is versatile enough to excel in both production floor and R&D lab environments. This model is widely used in industry to measure components such as lithography reticules, DVD blanks, plastic films, lens blanks, laser crystals, cell phone display windows, injection molded parts, and many others. The bench top design and intuitive automated scanning software make this product the best choice for day-in-day-out evaluation of small parts (up to 150 mm x 150 mm).

With two measurement range options available to choose from (High Sensitivity and Extended Range), the system is well suited to address the demanding requirements of your application. The optional high speed scanning package makes high spatial resolution scans (<1 mm grid spacing) practical. The system can also add an optional manual or automated tilt stage to extend its evaluation into non-normal access measurement of thin samples and to calculate specific parameters (such as Rth).

Features:

- Bench top design

- Flexible stage design for adding custom parts holders

- System Size WxDxH (mm) 715x350x360

- Max. Sample Size WxDxH (mm): 120x100

Exicor 250A

The Exicor 250AT is the ‘Step-up’ model of the Exicor® birefringence measurement system family of products. This model was developed to replace the obsolete Exicor 350AT and is widely used for lighter weight but larger samples such as plastic films. Built on the Exicor 150AT frame, this system incorporates a larger scan area (up to 250mm x 250mm) while maintaining the desk top nature of the Exicor 150AT system. This is also the system most customers select when they choose the Exicor ATS (spectroscopic measurements) option for studying birefringence at different wavelengths. The larger stage size also allows for loading multiple small parts on the stage and in conjunction with the optional Exicor Macro+ software to execute automated routines to scan each part individually. The user can begin the routine and let it run for multiple shifts, overnight or even longer (depending on the application) without having to intervene.

With two measurement range options available to choose from (High Sensitivity and Extended Range), the system is well suited to address the demanding requirements of your larger light weight samples. The optional high speed scanning package makes high spatial resolution scans (<1mm grid spacing) practical.

Features:

- Large and Flexible stage platform design for adding custom parts holders or process aids

- System Size WxDxH (mm) 1413x693x909

- Max. Sample Size WxDxH (mm): 150x150x150

Exicor 300AT

With two measurement range options available to choose from (High Sensitivity and Extended Range) the system is well-suited to address the demanding requirements of your large samples. The optional high speed scanning package makes high spatial resolution scans

Features:

- Heavy duty automated XY stage

- 3 side easy access stage loading design

- Large and flexible stage platform design for adding custom parts holders or process aids

- System Size WxDxH (mm) 1752x1270x1193

- Max. Sample Size WxDxH (mm): 300x300x150

The Exicor 500AT

The Exicor 500AT is the all new frame design replacing the Exicor 450AT systems. This new ‘Heavy Lifter’ of the Exicor® birefringence measurement system family brings a new efficiency and improved robustness to accommodate even larger and more numerous samples. This model is ideal for measuring thick lens blanks for lithography applications as well as other large and heavy parts (up to 500mm X 500mm and 400+mm thick). The 500AT improves on the proven frame and motion control components that are the hallmarks of the Hinds Instruments Exicor 450AT systems.

The new design has a full forward easy access stage that allows the sample measurement area to completely clear all potential obstacles on three sides and above the sample. The larger stage also allows for loading multiple parts at one time for batch scanning applications, as well as giving more clear access for production line automation integration applications. By adding the optional Exicor Zones™ software to the 500AT the system can be setup to execute automated routines to scan each part individually and assign individual file names to each ‘zone’. This software allows the user to begin the routine and let it run for multiple shifts, overnight or even longer (depending on the application) without having to intervene.

With two measurement range options available to choose from (High Sensitivity and Extended Range) the system is well-suited to address the demanding requirements of your large samples. The optional high speed scanning package makes high spatial resolution scans (<1mm grid spacing) practical.

Features:

- Heavy duty automated XY stage

- 3 side easy access stage loading design

- Large and flexible stage platform design for adding custom parts holders or process aids

- System Size WxDxH (mm) 1500x1500x1500

- Max. Sample Size WxDxH (mm): 500x500x500

Exicor® GEN

The Exicor® GEN5 and GEN6 systems are large format sample measurement units built on the core Exicor low level birefringence measurement technology and precision automated motion control elements. These platforms provide unsurpassed low level birefringence measurements to support the precision characterization of display related materials for the LCD industry (Generation 5+ compensation films and glass substrates, etc.) The systems are backward compatible with earlier generation models. The system designs are scalable to larger materials and can easily be adapted to other non-display material applications such as low tech sheeting materials and commercial window glass. With a scanable area of 1150 mm x 1375 mm, the GEN5 system uses a patented high tension wire grid stage to maximize the measurable area on the sample while minimizing the sample sag and flexure. With the optional high speed Scan In Motion™ (SIM) option, the system can characterize a sample in a fraction of the time a normal scanning would take (as little as 12 minutes, estimated).

|  |  |

Thickness and Warpage Option

OPTIONS:

- Exicor NEXUS Program

- Hinds Scan in MotionTM (High Speed Scanning)

- Thickness and Warpage Measurements

- Larger Stage Measurement Areas (Scalable beyond GEN 5) and custom stage designs

- Custom wavelengths (VIS, NIR)

- Custom Software (UI or DLL)

- Stress Estimation Calculation (PSI)

SPECIFICATIONS

| GEN5 | GEN6 | GEN9 | |

|---|---|---|---|

| Retardation Range: | 0.005 to 300 nm | ||

| Retardation Resolution / Repeatability1, 2: | 0.001 nm / ± 0.008 nm | ||

| Angular Resolution / Repeatability1: | 0.01º / ± 0.05º | ||

| Measurement Rate / Time3: | up to 100 pps / sample size dependent | ||

| Size (Foot print): | fits in a 2.2 m x 2.5 m work area | TBD | |

| Measurement area (mm): | 1150 x 1350 | 1550 x 1850 | 2500 x 3000 |

| Light Source Wavelength4: | 632.8 nm (HeNe Laser) | ||

| Measurement Spot Diameter5: | ~1 mm native (down to 100 µm) | ||

| Modulation Technique / Frequency: | Hinds Instruments PEMLabsTM Photoelastic Modulator / 50 kHz | ||

| Demodulation Analysis Technique: | Hinds Instruments SignalocTM Lock-in Amplifier | ||

| Measurement Units: | nm (retardation), º (angle) | ||

1 Typical performance at 5 nm retardation

2 Up to 1 nm, 1% thereafter.

3 Maximum data collection speed with options. Sample XY scan time dependent on stage movement parameters.

4 Custom wavelengths available

5 Spot sizes of less that 1mm native require optional high resolution detector module

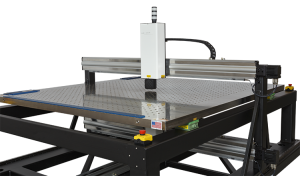

Exicor® HD

The newly designed Exicor® HD system is a heavy-duty sample measurement system based on Exicor's core low-level birefringence measurement technology and precision automated motion control elements. The design of the Exicor HD utilizes an all steel base to support heavy samples with a gantry which moves out of the way for ease of loading the sample via crane or rollers. This brings the Exicor birefringence measurement system family to a new level of efficiency and improved robustness to accommodate larger, heavier samples.

The HD’s sample dimensions will start with the 400HD at 400mm x 400mm x 400mm(x,y,z) with a max sample weight of 250lbs/113kg and will top out with the 2000HD at 2m x 2m x 500mm(x,y,z) with a max weight of 2,200lbs/1000kg. This new line of products makes the family of birefringence measurement systems more versatile than ever before.

The HD systems are also customizable to meet your every need. If your sample requires a vat for index matching fluid, we can customize the system to accommodate for your vat. Also available are custom wavelengths (VIS, NIR), as well as custom sample holders, and software customization (UI or DLL). Options for ease of loading your large sample on the HD system are available: a dropped front crossbar or adding HDPE pads on top of the crossbars.

| Motion | Model | Sample Dimensions | Maximum Weight | |

| X/Y | Z | |||

| Sample | 400HD | 400 x 400 | 400mm | 113kg |

| Sample | 600HD | 600 x 600 | 600mm | 225kg |

| Gantry | 800HD | 800 x 800 | 500mm | 340kg |

| Gantry | 1000HD | 1m x 1m | 500mm | 500kg |

| Gantry | 1500HD | 1.5m x 1.5m | 500mm | 750kg |

| Gantry | 2000HD | 2m x 2m | 500mm | 1000kg |

SPECIFICATIONS

| Retardation Range: | 0.005 to 300+ nm | ||

| Retardation Resolution / Repeatability1, 2: | 0.001 nm / ± 0.015 nm | ||

| Angular Resolution / Repeatability1: | 0.01º / ± 0.07º | ||

| Measurement Rate / Time3: | up to 100 pps / sample size dependent | ||

| Light Source Wavelength4: | Various (632.8 nm standard) | ||

| Measurement Spot Diameter5: | Between 1mm & 3mm native (can be as low as <50 µm) | ||

| Modulation Technique: | PEMLabsTM Photoelastic Modulator | ||

| Measurement Units: | nm (retardation),º (angle) | ||

| Loading Options: | Front and Overhead Options | ||

1 Typical performance at 5 nm retardation

2 Up to 1.5 nm, 1% thereafter.

3 Maximum data collection speed. Sample XY scan time dependent on stage movement parameters.

4 Custom wavelengths available

5 Measurement spot sizes of less than 1mm (native) require optional high resolution detector module

Exicor® OIA

Jest to system do pomiaru dwójłomności systemów optycznych, do oceny soczewek, optyki równoległej i optyki zakrzywionej przy normalnych i ukośnych kątach padania.

System oparty jest na nagrodzonej przez Hinds Instruments technologii pomiaru dwójłomności Exicor opartej na modulatorze fotoelastycznym (PEM). Ten system pomiaru dwójłomności nowej generacji zapewnia przemysłowi nowe możliwości w zakresie analizy i rozwoju soczewek litograficznych nowej generacji, półfabrykatów soczewek i drogocennej optyki. System wykorzystuje PEM do modulowania stanu polaryzacji wiązki światła oraz zaawansowaną elektronikę detekcji i demodulacji do pomiaru zmiany stanu polaryzacji przez optykę. Powoduje to pomiar opóźnienia optycznego jednego stanu polaryzacji względem drugiego pod kątem 90°. Za pomocą tych danych można ocenić dwójłomność i szybką orientację osi, a także teoretyczne naprężenia szczątkowe.

Hinds Instruments i technologia Exicor Oblique Incident Angle zostały wybrane do oceny dwójłomności optycznej w badaniach i produkcji przez światowych liderów w dziedzinie półfabrykatów soczewek litograficznych i gotowych soczewek.

The Hinds™ Instruments Exicor® OIA is the Premier Birefringence Measurement System for the evaluation of Lenses, Parallel Faced Optics and Curved Optics at normal and oblique incident angles. The system is built on Hinds Instruments award winning Photoelastic Modulator (PEM) based Exicor Birefringence Measurement technology. This next generation birefringence measurement system is providing the industry with new capabilities in the analysis and development of next generation lithographic lenses, lens blank and high value precious optics.

The system utilizes PEMs to modulate the polarization state of a light beam and advanced detection and demodulation electronics to measure how an optic has changed the polarization state. This results in the measurement of optical retardation of one polarization state relative to another at 90°. Birefringence and Fast Axis orientation, as well as theoretical residual stress, can be evaluated with this data.

Hinds Instruments and the Exicor Oblique Incident Angle Technology has been selected to evaluate optical birefringence in research and production by the world leaders in lithographic lens blanks and finished lenses. Our systems are surpassed by none!

SPECIFICATIONS

| VIS Retardation measurement range: | 0 to 300+nm | ||

| DUV Retardation measurement range: | 0 to 90+nm | ||

| VIS Retardation Resolution / Repeatability: | 0.001nm / ±0.03 (up to 3nm, 1% thereafter) | ||

| DUV Retardation Resolution / Repeatability: | 0.001nm / ± 0.08 nm (up to 4nm, 2% thereafter) | ||

| Retardation Accuracy: | Better than ±0.2nm expected | ||

| Angular Resolution / Repeatability: | 0.01° / <±0.5° | ||

| VIS Light Source Wavelength: | 632.8nm | ||

| DUV Light Source Wavelength: | 193nm | ||

| Modulation Technique/Frequency: | PEMLabsTM Photoelastic Modulator / 50/60 kHz | ||

| Demodulation Analysis Technique: | Hinds Instruments SignalocTM Lock-in Amplifier | ||

Standard Features:

- Exicor OIA Software

- Automatic scan of Parallel flats and Spherical lens types

- Asphere can be scanned with Manual macro program

- 2D Maps of retardation and fast Axis orientation

- Scan Statistics

- Stage Forward Load Position (free access to samples stage from above)

- UV and Laser Light Enclosure with safety Interlocks

- Emergency OFF shut down buttons

- System Status Light Tower

- User Work Station with Computer and Monitor

Exicor® PV-Si

Podczas produkcji krzemowych paneli słonecznych naprężenia w kryształach krzemu często pozostają niewykryte przez długi czas w procesie wytwarzania. Firma Hinds Instruments opracowała przyrząd do pomiaru dwójłomności naprężeń do pomiaru sztabek Si, zarówno w kształcie kwadratu, jak i w stanie wyrośniętym, zanim zostaną pocięte na wafle. Gdy ten instrument jest używany jako narzędzie kontroli jakości, można zidentyfikować wlewki lub segmenty Si niskiej jakości przed poniesieniem dalszych kosztów przetwarzania. Ponadto instrument ten zapewnia hodowcom kryształów krzemu narzędzie, za pomocą którego można poprawić jakość wlewków krzemowych, aby mogli wytwarzać cieńsze wafle przy niskiej mechanicznej utracie wydajności.

System pomiaru dwójłomności Exicor® w bliskiej podczerwieni firmy Hinds Instruments 500 Si Ingot jest rozszerzeniem platformy roboczej rodziny produktów systemów pomiaru dwójłomności Exicor. System ten wykorzystuje wysokiej jakości symetryczne modulatory fotoelastyczne, laser 1550 nm oraz fotodiodowy detektor lawinowy Ge, aby umożliwić bardzo dokładne pomiary dwójłomności materiałów krzemowych stosowanych zarówno w przemyśle fotowoltaicznym, jak i półprzewodnikowym. Oprócz Si, za pomocą tego systemu można również mierzyć materiały takie jak szafir, węglik krzemu, selenek cynku, siarczek kadmu. Model 500 Si Ingot jest solidny i wszechstronny, zbudowany do przechowywania i pomiaru surowych wlewków o długości 500 mm o średnicy do 8 cali. Konstrukcja systemu i intuicyjne oprogramowanie do automatycznego skanowania sprawiają, że ten produkt jest najlepszym wyborem do ulepszania materiałów, prac badawczo-rozwojowych i codziennej oceny surowych wlewków Si, a także innych materiałów zaawansowanych technologicznie.

During the production of Si solar panels, stress in Si crystals often remains undetected long into the fabrication process. Hinds Instruments has developed a stress birefringence instrument for measuring Si ingots, either squared or as-grown, before they are sawed into wafers. When this instrument is used as a QC tool, low quality Si ingots or segments can be identified before subsequent processing costs are incurred. In addition, this instrument provides growers of Si crystals a tool with which to improve the quality of Si ingots so they can produce thinner wafers with low mechanical yield loss.

Hinds Instruments’ Near Infrared Exicor® Birefringence Measurement System 500 Si Ingot is an extension of the workhorse platform of the Exicor birefringence measurement system family of products. This system employs high quality, symmetrical photoelastic modulators, a 1550 nm laser, and a Ge avalanche photodiode detector to enable high accuracy birefringence measurements for Si materials used in both the photovoltaic and semiconductor industries. In addition to Si, materials such as sapphire, silicon carbide, zinc selenide, cadmium sulfide can also be measured with this system. The 500 Si Ingot model is robust and versatile, built to hold and measure a 500mm length of raw ingot up to diameters of 8 inches. The system design and intuitive automated scanning software make this product the best choice for material improvement, R&D efforts and day-in-day-out evaluation of raw Si ingots as well as other high tech materials.

Features:

- Unprecedented sensitivity in low-level birefringence measurement

- Simultaneous measurement of birefringence magnitude and angle

- Precision repeatability

- High-speed measurement

- Automatic mapping of variable-sized optical elements

- Photoelastic modulator technology

- Simple, user-friendly operation

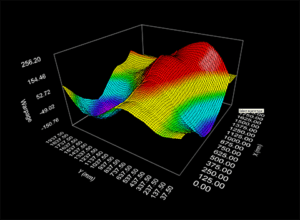

![]() Figure 1: Exicor scan of a silicon ingot.

Figure 1: Exicor scan of a silicon ingot.

SPECIFICATIONS

| Extended Range | |

| 1/2 Wave Systems | |

| Retardation Range | 0.1 to 775 nm |

| Resolution / Repeatability: | |

| Retardation1 | 0.1 nm |

| Fast Axis Angle | 0.01º at >10 nm |

| Measurement | up to 100 pps |

| Spot Size | ~2 mm typical |

| Sample Size | 500 mm x 150 mm for squared ingots / 500 mm x 210 mm for as-grown ingots |

1Up to 10 nm, 1% thereafter.

Exicor® MT

Systemy MT to modułowe jednostki z rodziny produktów systemów pomiaru dwójłomności Exicor. Systemy MT są sprzedawane wyłącznie klientom OEM, którzy kupują hurtowo. Modele te są szeroko stosowane w przemyśle do pomiaru elementów takich jak cienkie szkło, folie z tworzyw sztucznych, materiały sypkie, włókna i wiele innych.

The MT Systems are the modular units of the Exicor® birefringence measurement system family of products. The MT systems are only sold to OEM customers who buy in volume. These models are widely used in industry to measure components such as thin glass, plastic films, bulk material, fibers, and many others.

Exicor MT

The Exicor MT is designed for low level birefringence and stress birefringence measurements. This system is focused on thin glass, thick plastic and thin plastic films applications where low level resolution and repeatability are required to produce high tech materials and products.

Exicor MT-3

The Exicor MT-3 is designed for higher level birefringence applications up to half wave of the probe light. This system is focused on thick plastic and thin plastic films applications where low level to mid-level birefringence needs to be evaluated in one instrument.

Exicor MT-4

The Exicor MT-4 is designed to measure high levels of birefringence. This system is focused on plastic films and applications where retardation levels exceed the half wave value of the probe light. This system uses a unique, patented dual wavelength and orientation technique to measure birefringence magnitudes up to 4000 nm.

Exicor MT-5

The Exicor MT-5 is an integrated multi-source and multi-detector system. It is designed for web applications where multiple fixed measurement points are needed and traversing stages are either impractical or not an option.

Exicor MT-Custom

The MT family is designed to fully adapt to the demanding needs of industry. These systems are all easily adapted to your requirements and the demands of your application environment. The Exicor NEXUS programTM is available to help you integrate or develop processes using the Exicor family of products.

General Systems Features:

- DLL or UI software (2D and 3D graphical representation of birefringence parameters)

- Modular Design (Flexible mounting options for quick and custom integration)

- Well-suited for production line applications

SPECIFICATIONS

| Custom | MT-3 / MT-5 / Custom | MT - 4 | ||

|---|---|---|---|---|

| Retardation Range: | 0.005 to 120+ nm | 0.005 to 300+ nm | 0.1 nm to 4000 nm | |

| Retardation Resolution/ Repeatability1, 2, 2: | 0.001 / ± 0.008 nm | 0.001 / ± 0.008 nm | 0.1 nm / Contact Us | |

| Angular Resolution/ Repeatability1: | 0.01° / ± 0.05° | 0.01° / ± 0.07° | 0.1° / ± 0.5° | |

| Measurement Rate: | up to 100 pps | |||

| Light Source Wavelength3: | Various (633 nm standard) | 633 nm / 543 nm | ||

| Measurement Spot Diameter4: | Between 1 mm and 3 mm (can be as low as 50 µm) | 1 mm | ||

| Measurement Units: | nm (retardation),° (angle) | |||

1 Typical performance at 5 nm retardation

2 Up to 0.8 nm, 1% thereafter

3 Custom wavelengths available

4 Spot sizes of less that 1 mm native require optional high resolution detector module

OPTIONS:

- Additional Polarization Parameters

- Hinds Scan in Motion TM (High Speed Scanning)

- Spectroscopic and RGB measurements

- Custom wavelengths (VIS, NIR)

- Custom mounting brackets

- Custom Software (UI or DLL)

- Stress Estimation Calculations

Exicor® DUV

Systemy Exicor DUV i 193 DUV mierzą dwójłomność przy głębokich falach ultrafioletowych.

Nagrodzony w 2003 roku „R&D 100” system Exicor DUV został opracowany w celu oceny wewnętrznej dwójłomności materiałów soczewek zawierających fluorek wapnia (CaF2) przy długości fali 157 nm. Kolejny Exicor 193 DUV skupia się na różnorodnych materiałach stosowanych w systemach litograficznych 193 nm, zwłaszcza w systemach litografii immersyjnej 193 nm, które wymagają optyki najwyższej jakości. Oba te systemy spełniają zasadę „mierzenia długości fali użytkowej” wymaganą przez producentów precyzyjnych materiałów optycznych, którzy przesuwają granice technologii.

Systemy Exicor DUV i 193DUV są podstawowymi systemami używanymi przez wiodących producentów optyki w przemyśle litograficznym do pomiaru dwójłomności w materiałach półfabrykatów soczewek i półfabrykatów fotomasek przy długościach fal litograficznych DUV (157 nm, 193 nm, 248 nm). Systemy te są zbudowane z solidnej ramy i wytrzymałych komponentów sterowania ruchem do pomiaru optyki o wymiarach do 400 mm X 400 mm i grubości 200+ mm. System Exicor DUV wykorzystuje również unikalny zlokalizowany system wypierania tlenu w komorze próbki, ponieważ światło UV o długości fali 157 nm jest pochłaniane przez cząsteczki tlenu. To czyste, przedmuchane suchym azotem środowisko zapobiega również tworzeniu się ozonu w komorze próbki DUV. Oczyszczanie nie jest wymagane w przypadku pomiarów 193 nm i 248 nm.

The Exicor® DUV and 193 DUV systems measure birefringence at deep ultraviolet wavelengths. The 2003 "R&D 100" award winning Exicor DUV system was developed to evaluate intrinsic birefringence in Calcium Fluoride (CaF2) lens materials at the application wavelength of 157 nm. The subsequent Exicor 193 DUV focuses on a variety of materials used in 193 nm lithographic systems, especially immersion 193 nm lithography systems that demand the highest quality optics. Both of these systems satisfy the ‘measure at the wavelength of use’ principle demanded by precision optical materials manufacturers who are pushing the technology envelope.

The Exicor DUV and 193DUV systems are the primary systems used by the leading lithography industryoptics manufactures to measure birefringence in lens blank materials and photo-mask blanks at DUV lithographic wavelengths (157 nm, 193 nm, 248 nm). These systems are built with a robust frame and heavy duty motion control components for measuring optics up to 400 mm X 400 mm and 200+ mm thick. The Exicor DUV system also utilizes a unique localized oxygen displacement system in the sample chamber because 157 nm UV light is absorbed by oxygen molecules. This clean dry nitrogen purged environment also prevents the generation of ozone in the DUV sample chamber. Purging is not required for 193 nm and 248 nm measurements.

These systems’ large scanning stage also allows for loading multiple smaller parts on the stage, with the optional Exicor Macro+ software executing automated routines to scan each part individually. The user can begin the routine and let it run for multiple shifts, overnight or even longer (depending on the application) without having to intervene.

Features:

- Heavy Duty Automated XY stage

- Up to three selectable DUV wavelengths (157 nm, 193 nm, 248 nm)

- 2D and 3D graphical representation of birefringence parameters

- Advanced data analysis features included standard in user interface

- Large and adaptable stage platform design for adding custom parts holders or process aids

SPECIFICATIONS

| Exicor® DUV | Exicor® 193 DUV | |

| Wavelengths, selectable: |

|

|

| Retardation Range: |

|

|

| Retardation Resolution / Repeatability1, 2, 2: | 0.01 nm / ± 0.08 nm | 0.01 nm / ± 0.08 nm |

| Angular Resolution / Repeatability1: | 0.01º / ± 0.5º | 0.01º / ± 0.5º |

| Nitrogen (N2) Gas Purge: | Required (for 157nm measurements) | Not Required |

| Facility Exhaust: | Required (for N2 purge Gas removal) | Required (for Lamp ozone removal) |

| Size (mm): | 2150 (H) x 1600 (W) x 1220 (D) | 1900 (H) x 1350 (W) x 1350 (D) |

| Light Source: | 30 W Deuterium Lamp (N2 gas cooled) | 30 W Deuterium Lamp (air cooled) |

| Measurement Spot Diameter3: | 3 mm to 5 mm nominal(resolution can be as low as 1 mm) | |

| Modulation Technique / Frequency: | PEMLabsTM Photoelastic Modulator / 50 kHz and 50/60 kHz | |

| Demodulation Analysis Technique: | Hinds Instruments SignalocTM Lock-in Amplifier or Wave Form Capture Card | |

| Measurement Units: | nm (retardation),° (angle) | |

1 Typical performance at 5 nm retardation

2 Up to 4 nm, 2% thereafter

3Smaller spot sizes require additional averaging to achieve optimal repeatability

OPTIONS:

- Hinds Scan in MotionTM (High Speed Scanning)

- Custom Sample holders

- Custom Software (UI or DLL)

- Stress Estimation Calculations

Dostawcy